Balancing - BT Maskinteknik can help

BT Maskinteknik advises, among other things over a Schenk HM3BU dynamic balancing machine so we can help you or your company with precise balancing of a wide range of rotors. Our balancing machine is suitable for cylindrical rotors with their own axle studs and for balancing disk-shaped rotors on balance rings etc. To ensure optimal operating conditions on rotating equipment, it is extremely important to avoid harmful vibrations.

To minimize vibrations, BT Maskinteknik offers dynamic balancing of items up to 300 kg. The working range of our Schenck balancing machine is L2500, Diameter, max.1260, Weight max. 300 kg.

Help with balancing

Do you have single items, or larger batches that require balancing. Then we carry out both single order and subcontractor tasks that match your needs for help.

Why is balancing so important?

Why are some machines noisier than others? Why is the valve on the bicycle wheel always at the bottom when it has rotated? Why does the steering wheel of a car vibrate at certain speeds? One comes across the phenomenon almost daily. The effect of the mentioned things is imbalance.

The imbalance can cause more wear and tear on parts and thus danger to both machinery and people.

Lifetime - Bearings, suspensions, bearing housings, gaskets and foundations are affected by imbalance and vibrations, thereby exposing them to unnecessary wear and tear. Products with balanced parts always have a longer life. Therefore, it is important to get the imbalance corrected.

Security - Vibrations can reduce the friction between screws and nuts, so that the tension torque is reduced and the components separate. Electrical contacts lose connection with continuous vibration, wires lose connection at the clamping point. Imbalance can lead to operational disturbances - people and machines are exposed to danger.

Quality - A vibrating power tool cannot be used effectively. The user exerts themselves unnecessarily, increasing fatigue. Machine tools with vibrations have a negative effect on the finished result. A circular grinding machine or a milling machine with vibrations in their spindles gives poor quality and more waste of finished parts than if everything was balanced. Unbalanced forces, disturbing vibrations and noise are avoided by balancing. This improves a rotor's mass distribution so that less centrifugal forces occur in the bearings. When balancing, the nature of the imbalance must also be taken into account.

Causes of imbalance in the system

An imbalance in a machine occurs when the center of gravity of the mass on a rotating machine part is not on the axis of rotation. This therefore means that there is a "heavy spot" in the system which causes unnecessary vibrations.

The reason why there may be an imbalance in the system can, among other things, be be:

- Fitting and processing errors in connection with drilling out in shafts

- Eccentric parts

- Corrosion on rotating parts

- Dirt

To avoid vibrations, wear and errors. Is it therefore very important to have the rotor parts balanced - so that the balance is restored. Let BT Maskinteknik help you with this.

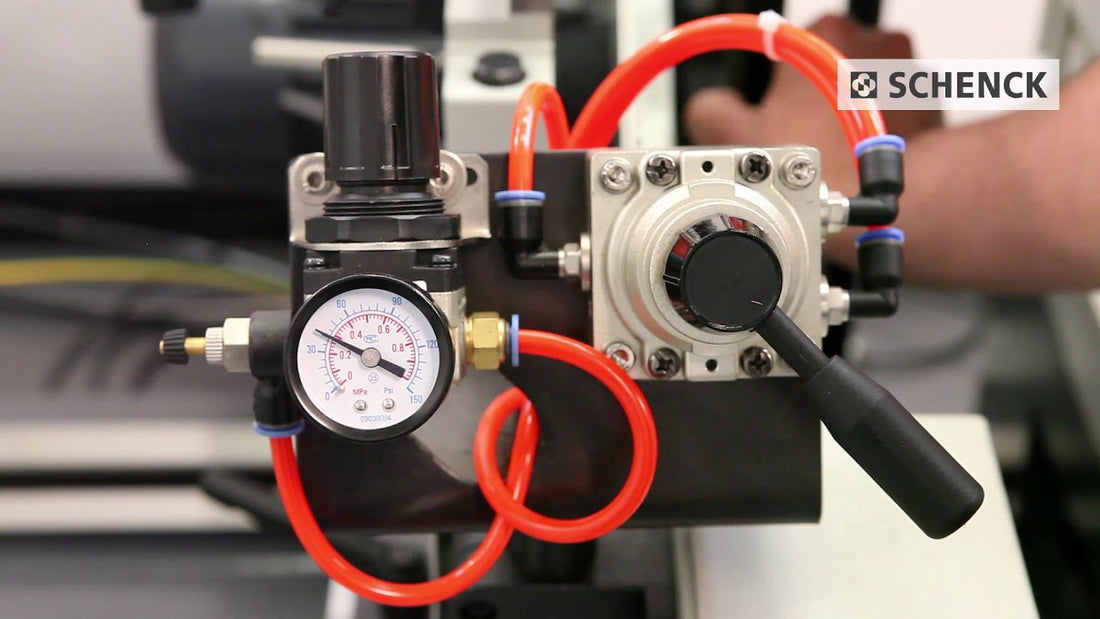

Schenck HM3BU Balancer

In 1907 Schenck produced their first balancing machine and here you can see one of their latest models the Schenck HM3BU balancing machine in action - The type BT Maskinteknik has: